Needs met by our Material Handling products

ALL ABOUT MATERIAL HANDLINGThat's how the products of the Material Handling System line are able to adapt and meet the most different needs related to material handling.

In the previous article we presented our Material handling System line. Let's discover now all the details of the different product categories and accessories!

Roller conveyors

In order to work in combination with the sawing machine and make the production process smoother, we designed a range of idler and motorized roller conveyors that can be installed both in the infeed and outfeed of the sawing machine. They are available both in length of 1500 mm for workloads up to 2000 Kg and in length of 3000 mm for workloads up to 4000 Kg.

They can work and be synchronized with Mep and/or other sawing machines and, thanks to their simple but heavy-duty structure, they can handle any kind of section and bundle.

Another important feature characterizing the range of roller conveyors is the possibility to customize and equip their standard version with several options allowing the installation of the conveyors even in hard environments and outdoor. The customization and addition of options can be made even after the installation of the systems. Among the main available accessories there are:

- Safety filler plates - ideal solution for a better handling of small pieces since they avoid the fall of the piece cut with a shorter length than the distance between the rollers (standard measure - 305 mm).

- Tray for coolant recovery - it is placed under the rollers to allow the total recovery of the coolant, thus preventing waste and dispersion of the coolant. This accessory is particularly recommended for those who need to cut tubes and bundles of materials.

- Vertical rollers - they are available in three different types that can be installed both in the infeed and outfeed of the sawing machine: vertical rollers to align and prevent the overturning of small and thin materials cut or to cut; heavy-duty vertical rollers to align and prevent the overturning of large materials (ideal for heavy-duty applications); adjustable vertical rollers allowing to contain and align bundles and thin materials with a circular cross section.

Controls

The MHS line is currently composed of two different types of user-friendly controls available on a fixed or movable stand. Both controls are the perfect solution for those who need to handle motorized roller conveyors both in the infeed and outfeed of the sawing machine.

On the one hand, the manual free stand control with joystick is ideal for simple systems with a low level of automation and it allows to handle the material while keeping the entire cutting line monitored. The free stand control is easy to handle and it is equipped with an anchor bracket to be placed wherever needed; moreover, the 6 meters of heavy-duty metal sheath allow maximum freedom of movement. As regards the functioning:

- By pushing the enable button and moving the joystick, the motorized roller conveyors are engaged.

- In case of roller conveyors in the infeed and outfeed, a selector allows to activate the infeed, outfeed or both.

- The potentiometric joystick allows to adjust the speed of the motorized roller conveyors.

- The emergency button stops the functioning of all the roller conveyors.

On the other hand, the fixed manual free stand control is ideal for systems with a higher level of automation. Free stand control with push buttons that, thanks to its heavy-duty structure, can be used even in hard production environments. As regards the functioning, by pushing the enable button and moving both the joystick and selector, the elements are engaged:

- In case of roller conveyors in the infeed and outfeed, a selector allows to activate the infeed, outfeed or both.

- The potentiometric joystick allows to adjust the speed of the motorized roller conveyors.

- The emergency button stops the functioning of all the cutting line.

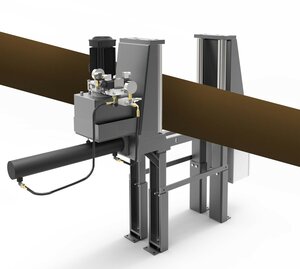

Squaring vices

Squaring vices were designed to contain and align bundles and/or heavy materials with a circular cross sections, which makes them ideal for heavy-duty applications. They can be installed both in the infeed and outfeed of the sawing machine and are available in three different sizes - 530 mm, 730 mm, 930 mm - and in the manual or automatic version. Moreover, they can be inserted inside the structure of a roller conveyor or between any section of the roller conveyor.

Material handling is powered by a hydraulic cylinder and the management is subject to the control selected. Moreover, each module is powered by its own hydraulic power unit to grant the functioning of the system in case of failure of any of them.

Staging skids

Designed for the stock of the material cut or to cut, staging skids can be installed both in the infeed and outfeed of the sawing machine and they are available in three different lengths: 1200 mm, 1500 mm and 2000 mm (standard version - 1500 mm). They are recommended for medium-low levels of automation and for jobs requiring operator intervention.

Staging skids are equipped with retractable restraint pins - which length and position can be customized - allowing to safely stock any kind of section.

Measuring systems

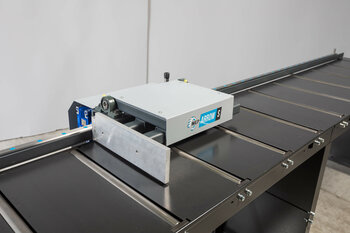

Our measuring system line is the ideal solution for those who need to accurately measure the values of the piece to cut. The range was previously composed of flip over stop devices with manual functioning and preset to be easily mounted on our unloading idler roller conveyors. Thanks to the recent launch of a new line of measuring systems, we managed to expand our range of products with both models with manual or programmable positioning and models with automatic continuous material feeding.

The new line of measuring systems is composed of two versions:

- "Light" measuring device ARROW can be mounted on our idler roller conveyors KK330 and KK460 and it is ideal for sawing machines with cutting capacity up to 350mm on medium-light materials. This measuring device is available with manual moving with digital visualization of the cutting measure (M model), with an automatic single (S model) or multiple (A model) positioning. Moreover, it can be equipped with several accessories.

- "Heavy-duty" measuring device BLAZE can be mounted on our roller conveyors KK530, KK730 and KK930 and it is ideal for sawing machines with cutting capacity up to 650mm on heavy materials. This measuring device is available with an automatic single (S model) or multiple (A model) positioning. Moreover, it can be equipped with several accessories. Due to its weight and size, the device cannot be flipped over by hand but only through an electronic device.

Stay tuned to discover more information about the new line of measuring systems!