Renewing to improve

Case historyContinuous need for innovation and confidence in the supplier: these are the main ingredients of our great experience with a Finnish customer.

The needs related to the cutting world are constantly evolving and it is therefore essential to be able to keep up with them, innovate through safe and profitable investments and, if necessary, go searching for special applications in order to optimize production. The ability to choose trusted suppliers plays a fundamental role in this process and this was the case of one of the latest collaborations with our Finnish dealer Prodmac.

Thanks to the relationship between Mep and our dealer Prodmac, a Finnish company mainly known for its expertise in the field of handrails has decided to renew his sawing machine fleet by relying on our machines. The customer needed to replace some old models in order to execute cuts on several materials faster, thus meeting the new market needs.

As a result of these needs, the customer initially chose two models: the automatic band sawing machine Shark 332-1 NC 5.0 and the semi-automatic band sawing machine Shark 282 SXI EVO. However, after less than a year, in order to optimize even more his sawing machine fleet, the customer decided to purchase another Mep model, that is the semi-automatic circular sawing machine Tiger 372 SX EVO.

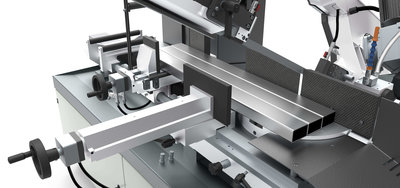

SHARK 332-1 NC 5.0

The customer chose this automatic band sawing machine thanks to its reliability and versatility allowing to work with both the automatic and manual modes. At the same time, also the ability of the machine to perform miter cuts played a fundamental role in the choice of this model.

Actually, the Shark 332-1 NC 5.0 is ideal to execute miter cuts on metals from -45° to +60° and it also combines accuracy with great cutting quality, without any compromise.

Why the Shark 332-1 NC 5.0

- The four working modes - manual, semi-automatic/dynamic, semi-automatic and automatic ones - allow to perform any kind of cut in the most efficient way.

- The automatic acquisition of the saw head cutting start position reduces setting time.

- The cast-iron adjustable blade-guide heads with 6 CARBINE pads ensure greater stability and longer blade life.

- The mechanical stops at -45°, 0°, +45° and +60° with locking device at all angles in between allow the quick positioning of the saw head.

- Angles scale engraved on the turning table allows to easily perform precise cuts in perfect tolerance at any angle.

SHARK 282 SXI EVO

Due to the need for miter cuts, the customer decided to purchase also this semi-automatic band sawing machine ideal to cut metals from -45° to +60°. In addition to the semi-automatic working mode, the Shark 282 SXI EVO can also work in semi-automatic/dynamic and manual modes.

Why the Shark 282 SXI EVO

- The turning cutting table is assembled on a central pin and roller thrust bearing thus allowing an easy and smooth rotation at any angle and turning along with the saw head thus preventing to cut it through.

- The clamping unit sliding longitudinally to the right and left of the saw head allows to safely perform even precise angle cuts.

- The main control with acustic commands is assembled on an articulated arm thus granting full control in all operational status.

- Machine designed for a complete recovery of chips and coolant.

TIGER 372 SX EVO

In this case, the customer purchased this model in order to replace an old circular sawing machine equipped with only two cutting speeds not suitable for some materials. The variable blade speed of our model and the customer’s need to make hundreds of cuts a day convinced him to choose this machine.

The Tiger 372 SX EVO is a semi-automatic vertical circular sawing machine that executes cuts on ferrous materials from -45° to +60° and combines power and cutting precision.

Together with the machine, the customer chose to invest also in the circular blade by purchasing a TCT circular saw blade. This blade is ideal to cut tough materials and to increase production but, at the same time, it requires an adequate structure and transmission system because carbide tips have a greater chip removal capability than those of a classic OV circular blade.

Why the Tiger 372 SX EVO

- The possibility to set the saw head stroke limits reduces cutting time.

- The adjustable steel anti-burr device clamps the material in the infeed and outfeed, thus granting a burr-free cut.

- The three-stage gear transmission allows to perform high-speed cuts and ensures longer blade life.

- The motion of the saw head on double linear guide with preloaded ball screw slides drastically reduces vibrations during the cut.

- The cast-iron structure absorbs vibrations and ensures greater cutting stability and longer blade life.

We appreciate the full trust on our range of sawing machines by the Finnish customer and we want to thank our dealer Prodmac for his professionalism and cooperation. As always, the experiences of our customers with our machines are extremely important inputs to make the field of application wider as well as to modify or to realize new models of machines.