SHARK 230-1 NC HS 5.0 and SHARK 350 NC HS 5.0: the comparison

ExhibitionsDiscover in detail two of our models that will be available at the exhibition EMO.

PRESENTATION OF THE MACHINES

|

|

SHARK 230-1 NC HS 5.0 |

SHARK 350 NC HS 5.0 |

|

MACHINE WEIGHT |

1.120 kg |

2.800 kg |

|

MACHINE SIZES |

|

|

|

BLADE SPECIFICATIONS |

|

|

|

BLADE MOTOR |

|

|

|

CUTTING CAPACITY |

|

|

|

SHARK 230-1 NC HS 5.0 |

SHARK 350 NC HS 5.0 |

|

Saw head structure in grey heavy-duty cast iron (G25) that absorbs vibration and grants greater cutting stability and longer blade life. Saw head powered by a hydraulic cylinder. |

Saw head structure in grey heavy-duty cast iron (G25) that absorbs vibration and grants greater cutting stability and longer blade life. Saw head powered by a hydraulic cylinder. |

|

Saw head assembled on a linear guide with preloaded ball screw slides in the powered side and on a mechanical guide at the front. |

Saw head assembled on double linear guides with preloaded ball screw slides. |

|

Steel base equipped with:

|

Steel base equipped with:

|

Material clamping

|

SHARK 230-1 NC HS 5.0 |

SHARK 350 NC HS 5.0 |

|

Machine equipped with a clamping device only in the infeed side. However, the sawing machine can be equipped with a split vice (OPTIONAL) to grant burr-free cuts. |

Standard machine equipped with a split vice to clamp the material either in the infeed or the outfeed of the sawing machine, thus granting burr-free cuts. |

|

Burnished and knurled steel jaws of both cutting and feeder vices to grant a proper clamping of the piece to cut. |

Burnished and knurled steel jaws of both cutting and feeder vices. Moreover, the jaws of the cutting vice can be replaced. |

Feeding system

|

SHARK 230-1 NC HS 5.0 |

SHARK 350 NC HS 5.0 |

|

Bar feeder with stroke 500 mm 19" (repeatable to cut at any length): cast-iron structure, stepper motor, screw assembled on preloaded opposing taper bearings and ball screw. |

Cast-iron bar feeder with stepper motor and ball screw. Multi-indexing up to 600mm (23") in a single stroke with automatic blade kerf compensation. |

|

Speed of the feeding vice: 4 m/min |

Speed of the feeding vice: 4.5 m/min |

|

Max. weight that the feeding vice can pull: 1360 Kg |

Max. weight that the feeding vice can pull: 2720 Kg |

Additional information

|

SHARK 230-1 NC HS 5.0 |

SHARK 350 NC HS 5.0 |

|

Manually-operated blade tensioning through electronic transducer displayed on the console. It ensures greater cutting precision and longer blade life.

|

Blade tensioning through a servo system constantly monitorized during the cutting cycle that ensures greater cutting precision and longer blade life. This system constantly monitors both blade tensioning during the cut according to the value set and its automatic releasing when in rest mode. |

|

Self-regulation in real-time of head down feed rate according to the type of material or blade wear. |

Self-regulation in real-time of head down feed rate according to the type of material or blade wear. |

|

Upon request, the machine can be equipped with the following kits:

|

Upon request, the machine can be equipped with the following kits:

|

|

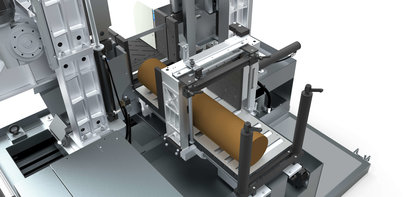

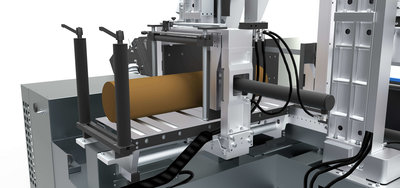

The machine can be equipped with the "Material Handling System" line: in particular, the sawing machine is suitable for products of the KK Line, entry-level line keeping the heavy-duty structure and both mechanical and electrical modularity from the K line. |

The machine can be equipped with the devices of the "Material Handling System" lines designed by Mep: on the one hand, there is the entry-level KK line; on the other hand, there is the K line, our top line thanks to its heavy-duty and highly customizable structure. |

DO YOU STILL HAVE DOUBTS?

Both machines are automatic band sawing machines for 0° cuts and they have been designed to meet the needs of mechanical workshops. However, while the Shark 230-1 NC HS 5.0 stands out for its optimized footprint (actually, the machine has a footprint of 2.5 sqm only); the Shark 350 NC HS 5.0 is characterized by high cutting speed and precision and it is ideal for medium-sized cutting (with sizes up to 350 x 350 mm).