ADAPTATIVE SAW HEAD DOWN FEED RATE

Self-regulation in real-time of head down feed rate according to the type of material or blade wear.

The automatic dual-column band sawing machine with a footprint of 2.5 sqm only: the winning combination between maximum performance and minimum space!

SHARK 230-1 NC HS 5.0, dual-column electrohydraulic automatic band sawing machine for 0° cuts of structural, stainless and alloy steels, solids and profiles. In addition to the automatic cycle, it can also operate in semi-automatic mode.

ABSOLUTE EFFICIENCY

> The two working modes (semi-automatic and automatic ones) allow to perform any kind of cut in the most efficient way.

> The control allowing to store up to 100 cutting programs, each one with different quantities and lengths, minimizes programming time of regular jobs.

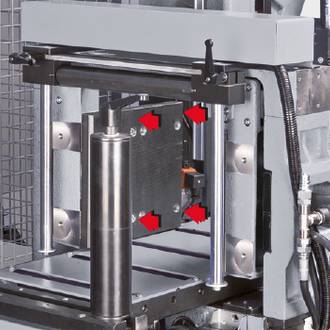

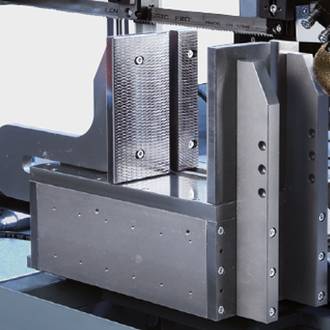

> The saw head motion is powered by a hydraulic cylinder on linear guides with preloaded ball screw slides and ensures a mechanical vibration reduction and stability during the cut.

> The automatic alignment of the front blade guide head according to the dimensions of the bars to cut reduces execution time.

EXCEPTIONAL FLEXIBILITY

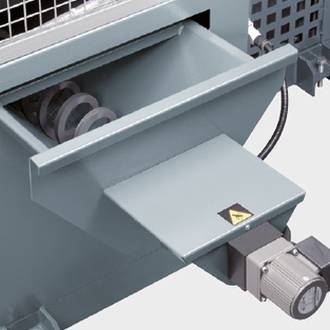

> The bar feeder with single stroke 600 mm is repeatable to cut at any length.

> The pair of vertical rollers allows to contain and align any kind of bar or bundle while feeding.

> The OPTIONAL automatic retract of the bar feeder fixed jaw allows to feed also non-straight bars.

> The vector inverter for infinite variable blade speed from 15 to 100 m/min allows to adjust the band saw blade rotation according to the type of material.

BOOK A DEMONSTRATION SESSION: TEST OUR SAWING MACHINES PERSONALLY AND DISCOVER ALL METAL CUTTING TECHNOLOGIES.

OUR TECHNICAL STAFF WILL BE READY TO GIVE YOU PERSONALIZED ADVICE ACCORDING TO YOUR NEEDS!

Self-regulation in real-time of head down feed rate according to the type of material or blade wear.

"Saw in the box" style that ensures maximum operator's safety according to the EC regulation and safety interlocks in accordance with the UNI 14119 regulation.

The optional IOT allows to maximize data collection and use them in favor of a better sawing machine cutting performance and longer blade life.

Great compactness thanks to a footprint of 2.5 sqm only.

| 0° | 230 mm | 230 mm |

| Max. vice opening | 235 mm |

| Minimum cutting length | 10 mm |

| Rest piece no longer feeded | 85 mm |

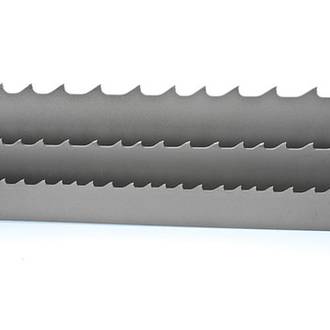

| Band size | 2950 x 27 x 0.9 mm |

| Blade motor power | 2.2 Kw - Three-phase |

| Blade rotation speed | 15 ÷ 100 m/min |