KONNECT CONTROL

Panel PC control, Quad core 2.0Ghz, 8-GB Ram, WINDOWS 10 and 17-inch touchscreen display with user-friendly graphic interface, which supports the operator during setting up, optimization and processing of various jobs.

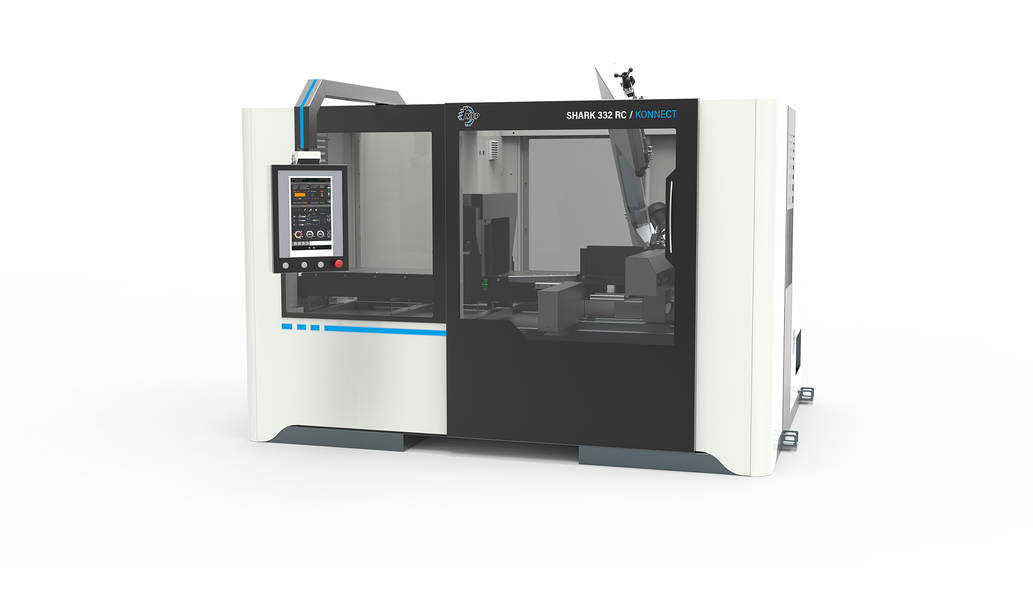

The pivot band sawing machine with double programmable mitering system that maximizes safety and strength for reliable performance and an always efficient smart manufacturing

SHARK 332 RC KONNECT, automatic electromechanical pivot band sawing machine with controlled automatic rotation to cut iron tubes, profiles and beams from -60° to +60°. In addition to the automatic operating cycle, it can also operate in semi-automatic mode.

ABSOLUTE EFFICIENCY

> Operator-free system: thanks to the auto-positioning of the saw head and vices as well as to the automatic handling of remnant and trim cut, the sawing machine functioning is completely automatized, thus minimizing the operator's intervention and setting times.

> INDUSTRY 4.0 READY

> The possibility to access to the after-sales service from remote through the main control of the sawing machine drastically reduces machine downtimes and service costs.

> Double cutting vice for optimal bar handling: the movable vice automatically spots itself according to the cutting angles set thus reducing machine set-up times; the fixed vice helps to better clamp the material during the cut by holding it while the bar feeder is moving.

> Adaptative saw head down feed rate: self-regulation in real-time of head down feed rate according to the type of material or blade wear through a servo motor on ball bearings screw drive, by adjusting it in real-time.

MAXIMUM FLEXIBILITY

> Dedicated software for the proper management of the various geometries of the materials according to the angles cut.

> Programmable automatic mitering of the saw head from -60° to +60° for symmetrical and asymmetrical cuts with servo motor that grants a precise control in speed, torque and positioning.

SAFETY GUARANTEED

> Preventive maintenance, which is based on real working time of the sawing machine and its components, promptly informs about necessary maintenance, thus allowing to minimize passive working times.

BOOK A DEMONSTRATION SESSION: TEST OUR SAWING MACHINES PERSONALLY AND DISCOVER ALL METAL CUTTING TECHNOLOGIES.

OUR TECHNICAL STAFF WILL BE READY TO GIVE YOU PERSONALIZED ADVICE ACCORDING TO YOUR NEEDS!

Panel PC control, Quad core 2.0Ghz, 8-GB Ram, WINDOWS 10 and 17-inch touchscreen display with user-friendly graphic interface, which supports the operator during setting up, optimization and processing of various jobs.

"Saw in the box" style that ensures maximum operator's safety, while maintaining excellent visibility and accessibility of all working areas.

The IOT allows to maximize data collection and use them in favor of a better sawing machine cutting performance and longer blade life.

| 0° | 310 mm | 300 mm | 330 x 300 mm | 230 x 310 mm |

| + 45° | 250 mm | 230 mm | 250 x 130 mm | 220 x 300 mm |

| + 60° | 160 mm | 155 mm | 160 x 80 mm | 140 x 290 mm |

| - 45° | 200 mm | 180 mm | 200 x 160 mm | 130 x 280 mm |

| - 60° | 130 mm | 110 mm | 140 x 80 mm | 40 x 250 mm |

| Max. vice opening | 330 mm |

| Minimum cutting length | 10 mm |

| Rest piece no longer feeded | 390 mm |

| Band size | 3770 x 27 x 0.9 mm |

| Blade motor power | 2.2 Kw - Three-phase |

| Blade rotation speed | 15 ÷ 100 m/min |

| Inverter power | 3.0 Kw |