SAW HEAD MANUAL MITERING

Cutting angle is set by manual mitering of the saw head through a handle and servo control for hydraulic locking.

Cutting angle showed on the display.

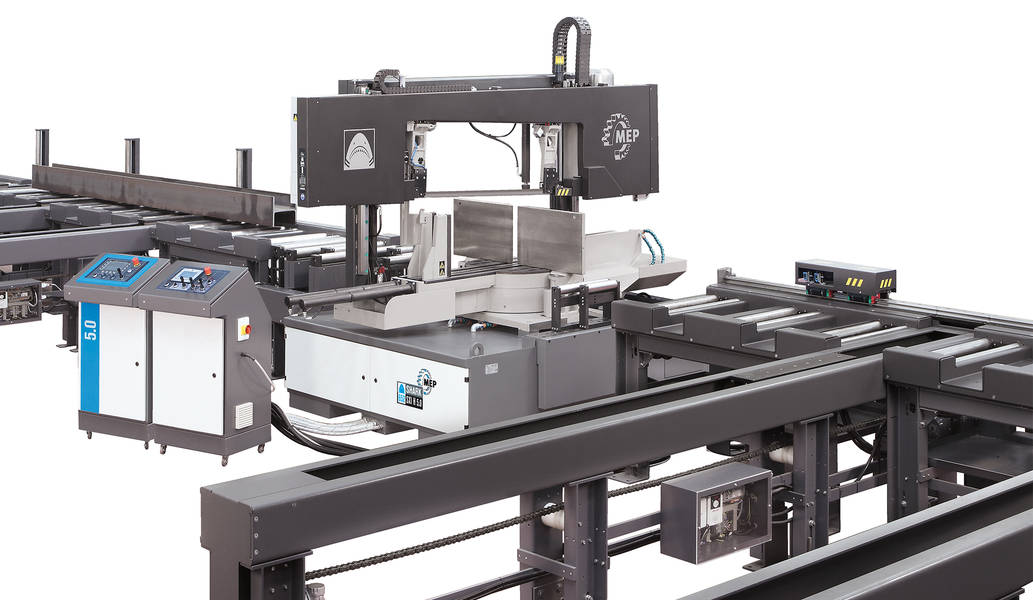

The semi-automatic band sawing machine ideal for the cut of large metal structures

SHARK 652 SXI H 5.0, dual-column electrohydraulic semi-automatic band sawing machine to cut tubes, profiles and beams mitering from -60° to +60°. In the optional AUTOMATIC POSITIONING mode, saw head mitering is executed automatically.

ABSOLUTE EFFICIENCY

> The automatic setting of the saw head upper position by means of a laser projector reduces programming time.

> The automatic alignment of the front blade guide head according to the dimension of the material to cut reduces setting time of the sawing machine.

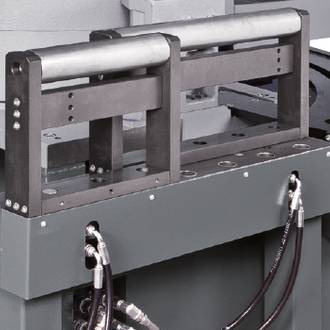

> The hydraulic clamping system is equipped with two independent vices on the left and on the right of the saw blade, thus allowing to safely execute precise and burr-free angle cuts.

> The coolant flood underneath the cutting table avoids the accumulation of chips and downtimes during the chip removal.

> The vector inverter for infinite variable blade rotation speed from 15 to 150 m/min allows to adjust the saw blade rotation speed according to the type of material.

EXCEPTIONAL FLEXIBILITY

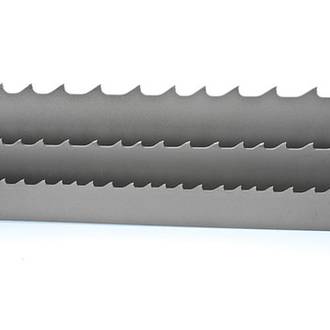

> The electromechanical servo system for the dynamic blade tensioning allows its continuous self-adjustment, thus ensuring greater cutting precision and longer blade life.

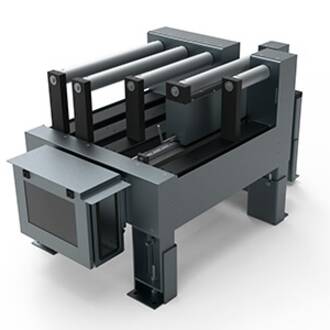

> The OPTIONAL system of hydraulic pop-up rollers lifts the bar from the working surface to avoid any kind of contact with the material during loading and unloading.

> The adaptative saw head feed force according to the resistance encountered by the blade during the cut allows to perform cuts with excellent finishing in any condition, even in case of worn-out blade.

> The junction between the cutting vice and the vertical support of the front blade guide head reduces setting time of the sawing machine, thus allowing their automatic positioning according to the section to cut.

BOOK A DEMONSTRATION SESSION: TEST OUR SAWING MACHINES PERSONALLY AND DISCOVER ALL METAL CUTTING TECHNOLOGIES.

OUR TECHNICAL STAFF WILL BE READY TO GIVE YOU PERSONALIZED ADVICE ACCORDING TO YOUR NEEDS!

Cutting angle is set by manual mitering of the saw head through a handle and servo control for hydraulic locking.

Cutting angle showed on the display.

With the optional AUTOMATIC POSITIONING (cutting angle programming from control panel with hydraulic locking of the saw head), the cutting angle is reached by means of a rack and chain transmission.

Two cutting cycles are available:

A) automatic cycle for single miter cuts;

B) automatic cycle for 2 miter cuts to be executed alternatively.

Cast-iron structure to absorb vibrations and ensure maximum cutting stability and longer blade life.

Motion of the saw head on linear guides with preloaded ball screw slides, powered by two hydraulic cylinders: 3-degree canted saw head suitable to cut the horizontal sides of bars or bundles.

Base and turning table designed to allow both a better chip removal from the working table and complete recovery of the coolant.

| 0° | 450 mm | 450 mm | 650 x 450 mm |

| + 45° | 400 mm | 400 mm | 400 x 450 mm |

| + 60° | 250 mm | 250 mm | 250 x 450 mm |

| - 45° | 400 mm | 400 mm | 400 x 450 mm |

| - 60° | 250 mm | 250 mm | 250 x 450 mm |

| Max. vice opening | 660 mm |

| Band size | 6700 x 41 x 1.3 mm |

| Blade motor power | 9.2 Kw - Three-phase |

| Blade rotation speed | 15 ÷ 150 m/min |