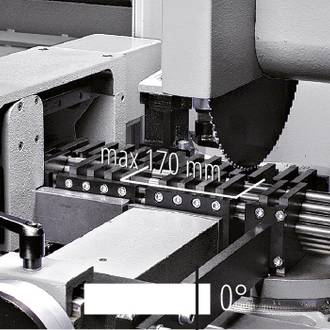

SAW HEAD MOTION ON TWO LINEAR GUIDES

The motion of the saw head on double linear guide with preloaded ball screw slides drastically reduces vibrations during the cut.

The super compact vertical circular sawing machine for the cut of metals that has always distinguished itself for its heavy-dutiness and accuracy

TIGER 352 NC 5.0, electropneumatic automatic vertical circular sawing machine to cut metals mitering from -45° to +60°. In addition to the automatic cutting cycle, it can also operate in the semi-automatic mode.

MAXIMUM PRODUCTION

> The cast-iron structure absorbs vibrations and ensures greater cutting stability and longer blade life.

> The two-stage transmission system allows to perform high-speed cuts and ensures longer blade life.

> The control allowing to store up to 100 cutting programs, each one with different quantities and lengths, minimizes programming time of regular jobs.

> The vector inverter for infinite variable blade speed from 12 to 120 m/min allows to adjust the saw blade rotation speed according to the type of material.

MAXIMUM PRECISION

> The bar feeder powered by a stepper motor is a guarantee of great precision.

> The turning cutting table is assembled on a central pin and thrust bearing thus allowing an easy and smooth rotation at any angle and turning along with the saw head thus preventing to cut it through.

> The mechanical stops at -45°, 0°, +45° and +60° with locking device at all angles in between allow the precise positioning of the saw head.

> Angles scale engraved on the turning table allows to easily perform precise cuts in perfect tolerance at any angle.

> The adjustable steel anti-burr device clamps the material in the infeed and outfeed, thus granting a burr-free cut.

BOOK A DEMONSTRATION SESSION: TEST OUR SAWING MACHINES PERSONALLY AND DISCOVER ALL METAL CUTTING TECHNOLOGIES.

OUR TECHNICAL STAFF WILL BE READY TO GIVE YOU PERSONALIZED ADVICE ACCORDING TO YOUR NEEDS!

The motion of the saw head on double linear guide with preloaded ball screw slides drastically reduces vibrations during the cut.

The optional IOT allows to maximize data collection and use them in favor of a better sawing machine cutting performance and longer blade life.

The turning table is assembled on a central pin and thrust bearing for an easy and precise rotation.

2.6 KW motor insulation class IP55 with vector inverter and mechanical gearbox for infinite variable blade speed from 12 to 120 rpm.

| Ø | ||||||||

| 0° | 350 | 115 mm | 95 mm | 180 x 95 mm | 90 mm | 90 mm | ||

| + 45° | 350 | 110 mm | 95 mm | 125 x 95 mm | 64 mm | 64 mm | 64 x 90 mm | |

| + 60° | 350 | 90 mm | 90 mm | 90 x 90 mm | 90 x 95 mm | 45 mm | 45 mm | 45 x 90 mm |

| - 45 ° | 350 | 110 mm | 95 mm | 125 x 95 mm | 64 mm | 64 mm | 64 x 90 mm |

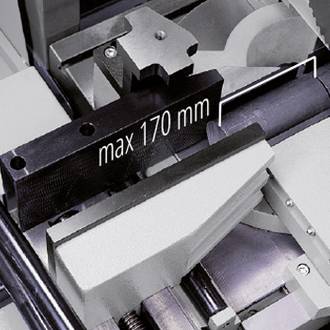

| Max. vice opening | 190 mm |

| Rest piece no longer feeded | 320 mm |

| Circular blade size | HSS 350 x 32 x 2.5 mm |

| Blade motor power | 2.6 Kw - Three-phase |

| Blade rotation speed | 12÷40 - 36÷120 rpm |

| Inverter power | 3.0 Kw |